5 Safety Tips When Using Formaldehyde Detectors

14th Nov 2023

Formaldehyde, a volatile organic compound (VOC), is ubiquitous in various industrial situations due to its diverse applications. A VOC is a type of chemical substance that can evaporate into a gas or vapor at room temperature. VOCs can significantly contribute to indoor air pollution.

Formaldehyde’s potential health risks necessitate using specialized gas detectors to monitor its concentration in the environment. Learn the importance of this device and five safety tips when using formaldehyde detectors.

Understanding Formaldehyde Detectors

Formaldehyde monitors are instruments designed to measure the concentration of formaldehyde gas in the air. They utilize sensors that react with formaldehyde gas to produce an electrical signal, which is then converted into a digital reading. This real-time measurement helps monitor indoor air quality for better health and safety.

Uses for Formaldehyde

Formaldehyde has the ability to kill most bacteria and fungi, which makes it an effective disinfectant and preservative. Furthermore, formaldehyde can readily react with many other chemicals, and it is often used in the production of resins and plastics due to its property of enhancing the durability and stability of these materials. You can find formaldehyde in various household products and materials, including paints, coatings, and paper products.

It is used as a preservative in medical laboratories and mortuaries and is found in chemicals, particle board, and household products. Moreover, it is present in the emissions from industrial facilities and is a significant component of automobile and aircraft exhaust emissions.

The Dangers of Formaldehyde

Breathing in even small amounts of this harmful gas can result in adverse health effects ranging from nose, throat, and eye irritation to more serious conditions, such as respiratory problems and even cancer. These alarming health risks make it critical to accurately detect gas levels to protect ourselves and our loved ones. Failure to follow safety guidelines related to using formaldehyde monitors could lead to inaccurate readings, false alarms, or even malfunctioning detectors, putting your health at risk.

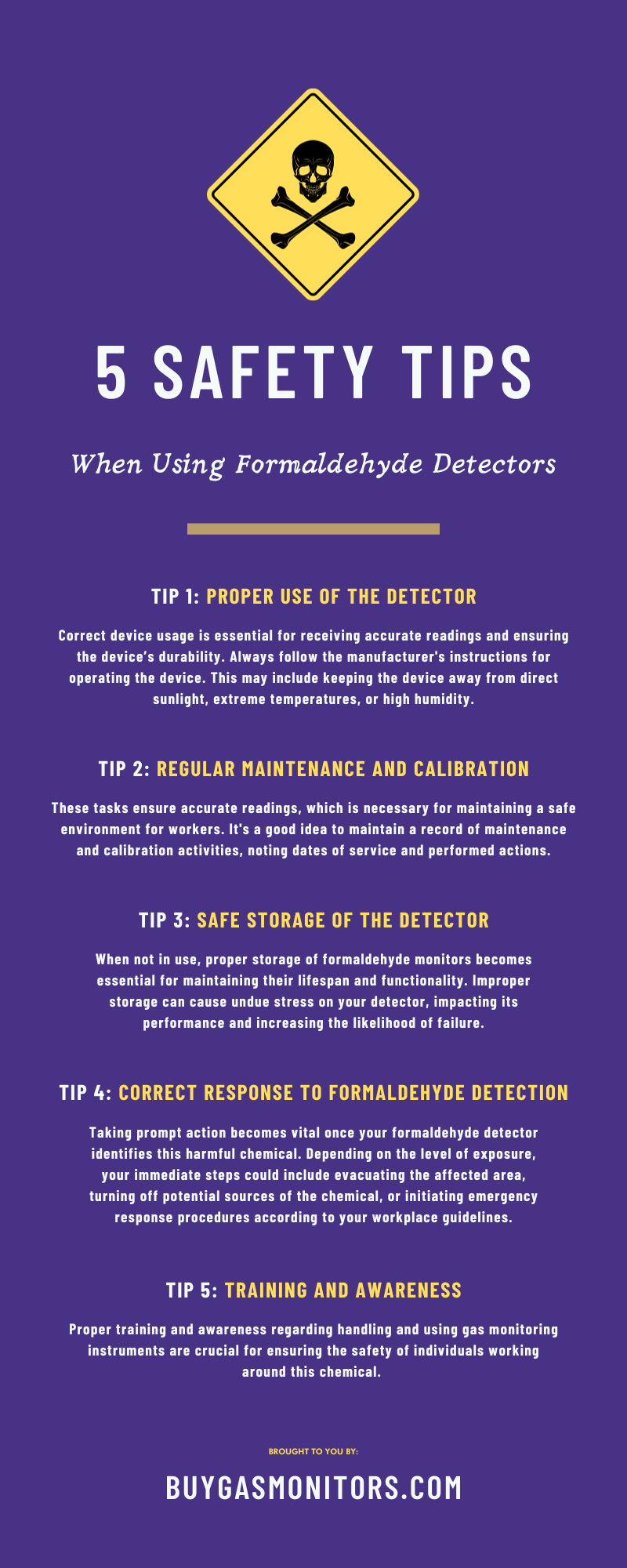

Tip 1: Proper Use of the Detector

Correct device usage is essential for receiving accurate readings and ensuring the device’s durability. Always follow the manufacturer's instructions for operating the device. This may include keeping the device away from direct sunlight, extreme temperatures, or high humidity.

Some formaldehyde detectors require time to warm up and stabilize before taking any measurements. Rushing through this process could give misleading results. Refer to the user manual to understand the proper warm-up time for your specific detector.

Usage Instructions Depend on the Detection Method

Formaldehyde detectors can use different techniques to measure concentrations of the gas. The steps the operator must take depend on the type of monitor in use. It is easiest to follow the manufacturer’s guidelines to ensure proper use of your specific device.

For example, when operating a detector that uses the photoelectric photometry method, the operator will place a colorimetric tablet into the instrument. Then, a sample of air from the test site will flow over the tablet for a specific time, such as 15 or 30 minutes. The device sensor will convert readings of color changes on the tablet to a readout displayed on the monitor screen.

Tip 2: Regular Maintenance and Calibration

Another safety tip when using formaldehyde detectors is to keep up with regular maintenance and calibration. These tasks ensure accurate readings, which is necessary for maintaining a safe environment for workers. It's a good idea to maintain a record of maintenance and calibration activities, noting dates of service and performed actions.

Cleaning and Inspections

Regular cleaning is essential for maintaining full functionality. This could involve a daily cleaning with cold water and a sponge and a more thorough cleaning on a monthly schedule. Additionally, workers should inspect the device every day for any signs of wear or damage, and qualified service personnel should address any issues found.

Calibration

Over time, sensors can lose their sensitivity. Calibration ensures the sensor's accuracy by setting it to a known concentration of the gas and adjusting the device's response to match this benchmark. Make sure to calibrate the device according to the manufacturer's recommendations.

For a formaldehyde gas monitor, calibration usually involves exposing the device to a known concentration of formaldehyde gas in a controlled environment. The readings are then adjusted until they match the known concentration, ensuring accurate future measurements.

Tip 3: Safe Storage of the Detector

When not in use, proper storage of formaldehyde monitors becomes essential for maintaining their lifespan and functionality. Improper storage can cause undue stress on your detector, impacting its performance and increasing the likelihood of failure.

To store a portable gas monitor appropriately, you should keep it in a climate-controlled environment. Excessive temperatures and humidity can rapidly damage the internal sensors of the device.

You should also keep the device away from areas with high humidity, dust, or corrosive gases, as these environmental factors may affect the detector's performance. Furthermore, it is not advisable to store the device in places that are difficult to reach or where the monitor could potentially be knocked over or damaged.

Tip 4: Correct Response to Formaldehyde Detection

Taking prompt action becomes vital once your formaldehyde detector identifies this harmful chemical. Depending on the level of exposure, your immediate steps could include evacuating the affected area, turning off potential sources of the chemical, or initiating emergency response procedures according to your workplace guidelines.

Following evacuation, you should report the situation to your supervisor or the appropriate safety personnel to ensure proper steps are taken to address the issue. Lastly, it is crucial that the area is not reentered until a professional has confirmed the formaldehyde levels have been reduced to a safe level.

Tip 5: Training and Awareness

Proper training and awareness regarding handling and using gas monitoring instruments are crucial for ensuring the safety of individuals working around this chemical. Those using these devices must be knowledgeable about their functions, modes, optimal calibration methods, and appropriate responses in case of detection.

Sources of training can include manufacturer-provided resources, industry workshops, or online courses on the safe handling of hazardous materials. Staying informed and spreading awareness about the risks associated with formaldehyde exposure and the importance of using detectors can help prevent accidents and fatalities.

When used correctly, well-maintained formaldehyde detectors provide accurate, real-time monitoring of formaldehyde gas concentration. Effective use involves following the manufacturer's instructions, conducting regular maintenance and calibration, and practicing safe storage. Additionally, workers must know the importance of prompt action upon detection and receive training on device use. The ultimate goal is to foster safer industrial environments and protect the well-being of individuals exposed to formaldehyde in their daily activities.