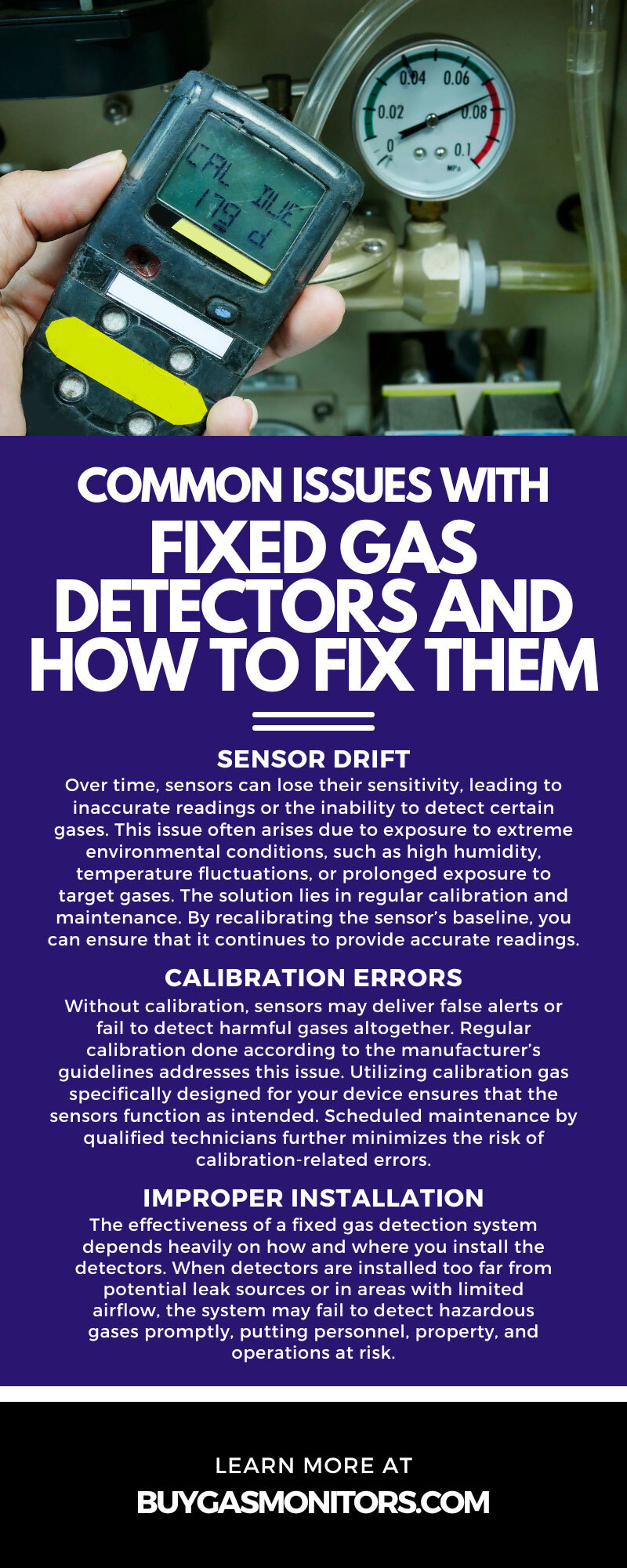

Common Issues With Fixed Gas Detectors and How To Fix Them

16th Jun 2025

Fixed gas detection systems are invaluable tools for ensuring safety and security in industrial environments. These devices help monitor potentially hazardous gases and provide early warnings to prevent accidents and ensure a safe workplace. However, as with any technical equipment, they can sometimes encounter issues that hinder their performance. Understanding common issues with fixed gas detectors and how to fix them promptly is crucial to maintaining their efficiency and reliability.

Sensor Drift

One of the most frequent issues with fixed gas detectors is sensor drift. Over time, sensors can lose their sensitivity, leading to inaccurate readings or the inability to detect certain gases. This issue often arises due to exposure to extreme environmental conditions, such as high humidity, temperature fluctuations, or prolonged exposure to target gases. The solution lies in regular calibration and maintenance. By recalibrating the sensor’s baseline, you can ensure that it continues to provide accurate readings.

Calibration Errors

Without calibration, sensors may deliver false alerts or fail to detect harmful gases altogether. Regular calibration done according to the manufacturer’s guidelines addresses this issue. Utilizing calibration gas specifically designed for your device ensures that the sensors function as intended. Scheduled maintenance by qualified technicians further minimizes the risk of calibration-related errors.

Improper Installation

The effectiveness of a fixed gas detection system depends heavily on how and where you install the detectors. When detectors are installed too far from potential leak sources or in areas with limited airflow, the system may fail to detect hazardous gases promptly, putting personnel, property, and operations at risk.

To ensure reliable performance, you must position detectors according to the specific characteristics of the gas in question. Heavier gases such as propane sink and accumulate near the floor, while lighter gases such as methane rise.

For example, a food processing plant manager may attempt to install ammonia gas detectors without consulting professionals and place the sensors at chest height throughout the facility. However, because ammonia is lighter than air, the gas would rise above the sensor range during a minor leak, delaying detection.

In this scenario, the company should instead hire certified technicians to position the sensors near the ceiling. This way, the system can successfully detect a leak within seconds, allowing staff to respond quickly and avoid operational disruptions. This scenario highlights how proper installation directly impacts safety and performance.

Signal Interference

Signal interference is another issue that can affect the performance of fixed gas detection systems. This problem often occurs in industrial environments where electromagnetic interference from equipment such as motors, radios, or Wi-Fi devices is present.

Signal interference can lead to missed alerts or inaccurate readings. Shielding the system’s wiring and ensuring proper grounding during installation helps minimize interference. Additionally, choosing high-quality detectors designed to withstand industrial conditions further reduces susceptibility to such disruptions.

Power Supply Challenges

Fixed gas detectors require a consistent power supply to function effectively, but power issues can occasionally cause malfunctions. Power surges, interruptions, or varying voltage levels may damage the system or disrupt its performance. Using an uninterruptible power supply (UPS) ensures continued operation during power outages. Routine checks of power sources and wiring also help prevent electrical supply problems.

Sensor Contamination

Sensor contamination is another concern that affects the accuracy of gas detection systems. Exposure to high levels of dirt, dust, or chemical vapors in industrial environments can block sensor pathways or degrade their components, potentially compromising their functionality. Regular cleaning and routine maintenance can mitigate contamination. If contamination persists, replacing the sensor is often the best course of action to restore optimal functionality.

Response Time Delays

A delayed response from your fixed gas detection system can pose serious risks. Prolonged exposure to hazardous gases while awaiting an alert is a situation no business should face. Factors such as sensor aging, contamination, or improper placement can all contribute to slow response times. Regular testing ensures that response times meet safety standards. Replacing outdated sensors or repositioning detectors can also address this issue.

Environmental Conditions

Extreme environmental conditions can significantly impact the performance of fixed gas detectors. High humidity, corrosive substances, or extreme temperatures may cause sensor degradation or shorten their lifespan. Choosing detectors that are specifically designed for the environmental conditions of your facility is essential. Additionally, protective enclosures can shield devices from harsh external factors, prolonging their durability and ensuring precise operation.

Human Error in Maintenance

Human error during system maintenance is another common factor affecting gas detection systems. Improper calibration, cleaning, or handling can result in faulty readings or damage to the device. Training staff in proper handling procedures and employing experienced professionals for servicing minimizes the likelihood of human error. Detailed records of each maintenance activity also help track the system’s performance over time.

Outdated Systems

Some businesses may still rely on earlier models of fixed gas detection systems, which might lack the advanced features and precision of modern devices. These older systems may not adapt well to current safety requirements or struggle to detect newer industrial chemicals. Upgrading to newer models with advanced sensor technology and built-in self-monitoring features can enhance workplace safety and align your system with regulatory standards.

False Alarms

False alarms are inconvenient and may lead workers to become desensitized to alerts, potentially compromising their ability to respond effectively. Factors such as interference, poor calibration, or sensor placement in inappropriate locations often trigger false alerts. Addressing these underlying causes through regular troubleshooting and adherence to installation guidelines can significantly reduce the occurrence of false alarms.

Lack of a Preventative Maintenance Schedule

The absence of a preventative maintenance schedule means that equipment failures may go unnoticed until they lead to serious safety risks. Establishing a comprehensive maintenance strategy, including regular inspections, calibration, sensor replacements, and performance testing, ensures the long-term reliability of your system.

Proactively managing a fixed gas detection system is crucial for maintaining a safe and productive work environment. Investing in proper training, professional installation, and regular maintenance prepares your organization to handle gas-related risks effectively. Taking the time to understand and resolve these common issues with fixed gas detectors will ensure that your system operates at peak performance, delivering the safety and peace of mind you need.