A Step-by-Step Guide to Cleaning Fixed Gas Detectors

20th Feb 2026

Mechanical contractors and safety directors rely on accurate gas readings to protect people, property, and operations. A neglected detector can drift out of tolerance, trigger false alarms, or fail to respond during a leak.

A step-by-step guide to cleaning fixed gas detectors helps teams maintain optimal performance and extend equipment life. TG Technical Services specializes in gas monitoring devices and understands how proper maintenance supports safe work sites. This guide explains how to clean your equipment correctly, avoid common mistakes, and keep your system ready for real-world conditions.

Read and Understand the Manufacturer’s Recommendations

Every fixed gas detection system includes specific cleaning and maintenance instructions. Manufacturers design sensors and housings with materials that respond differently to moisture, chemicals, and abrasion. Review the product manual before you begin any cleaning process. Confirm the approved cleaning agents, tools, and inspection intervals.

Follow the recommended maintenance schedule to prevent buildup that interferes with sensor performance. Some detectors require more frequent attention in dusty or corrosive environments.

Document each cleaning session in your maintenance log to maintain compliance and track performance trends. Clear records help safety directors demonstrate due diligence during inspections or audits. Careful adherence to these guidelines reduces the risk of unexpected failures and keeps your gas detection system dependable when it matters most.

Power Down and Prepare the Area

Always shut down the detector according to the manufacturer’s instructions before cleaning. Disconnect the power sources to reduce the risk of electrical damage or accidental alarms. Notify team members if the system connects to a building management or alarm system.

Prepare the surrounding area to prevent debris from entering the sensor chamber during cleaning. Use personal protective equipment, especially in environments with residual gas exposure.

Keep cleaning materials organized and within reach to reduce unnecessary movement around the equipment. Careful preparation protects both the technician and the device. Post clear signage and communicate the maintenance schedule to all relevant personnel, ensuring that everyone is aware when detectors are offline for cleaning.

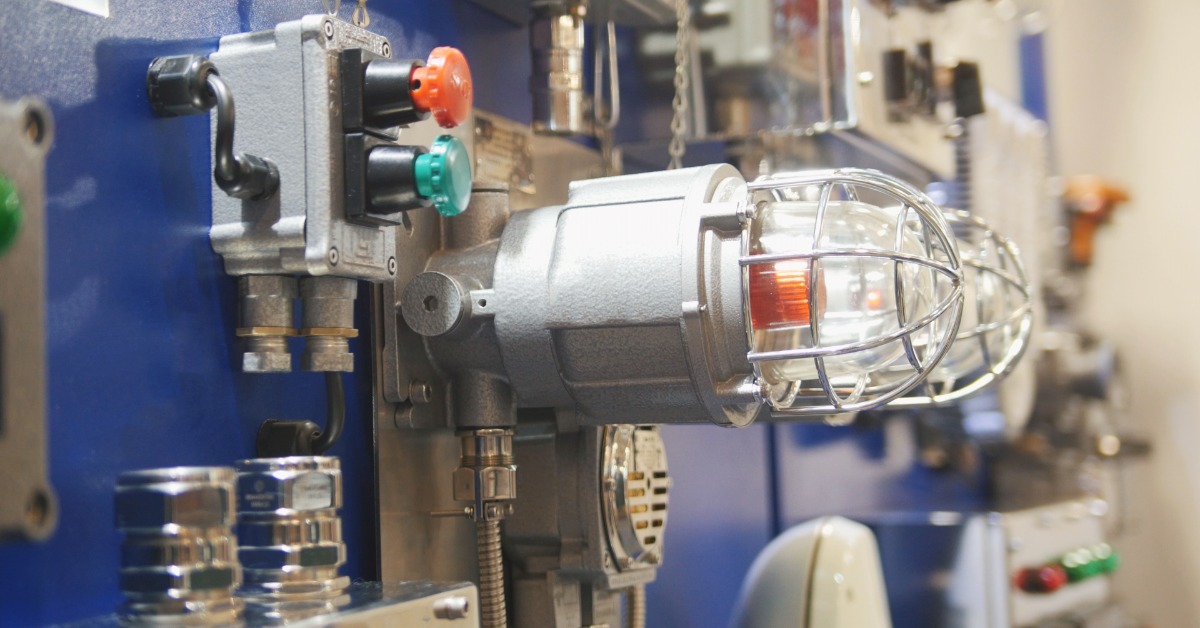

Inspect the Detector for Damage and Debris

Begin with a thorough visual inspection of the unit. Look for dust buildup, corrosion, cracked housings, loose wiring, or clogged sensor openings. Harsh environments such as parking garages, agricultural facilities, and industrial sites can accelerate wear.

Pay close attention to sensor inlets and protective screens. Blocked openings restrict airflow and delay gas detection. Use a soft brush or dry compressed air to remove loose debris from exterior surfaces. Avoid inserting sharp objects into sensor ports.

Detecting physical damage early lets you address minor issues before they cause system failure. Consistent inspections can also reveal recurring patterns, allowing you to adjust your cleaning frequency or protective measures to suit your facility’s conditions.

Clean External Surfaces and Sensor Housings

After inspection, clean the exterior housing with a soft cloth and a manufacturer-approved solution. Wipe down the mounting brackets and surrounding surfaces where dust and grime build up. Avoid soaking the unit or allowing liquid to seep into internal components.

For heavily contaminated environments, use a mild detergent solution approved by the manufacturer. Rinse lightly with a damp cloth and dry the surface completely. Moisture left behind can corrode components or interfere with readings. Keep the cleaning process controlled and deliberate to protect sensitive electronics.

Use these basic cleaning principles:

- Use non-abrasive cloths and soft brushes.

- Apply only approved cleaning agents.

- Prevent liquid from entering sensor openings.

- Dry all surfaces completely before restoring power.

Following these basic guidelines helps keep your gas detection equipment working properly without risking damage to the device. Spending a little extra time on cleaning helps your detectors last longer and makes the workplace safer for everyone on your team.

Handle the Sensor Components Carefully

Sensor elements require extra care because they directly measure gas concentrations. Follow the manufacturer's guidelines for cleaning or replacing filters and splash guards. Some systems include removable components that you can clean separately.

If your facility uses a stationary gas detector in a high-dust or high-humidity environment, inspect the filters more frequently. Replace components that show signs of clogging or chemical damage.

Never attempt to recalibrate or disassemble sensor elements unless you have the proper training and authorization. Carefully managing sensors helps them stay accurate and ensures your system runs smoothly without unexpected interruptions. Consistently monitoring connectors and wiring can also help you identify early signs of wear or corrosion before they affect sensor performance.

Perform Calibration and Functional Testing

Cleaning your detector is important, but it’s just one part of keeping your system functioning properly. Once cleaning is finished, restore power and give the system a few moments to stabilize. Then, perform a bump test or full calibration according to the manufacturer’s instructions.

Make sure the detector responds accurately to tests and that all alarm setpoints, lights, and sounds are functioning as they should. Record your calibration results and any issues you notice.

If something seems off or readings are outside the expected range, arrange for professional servicing right away. By regularly testing your system, you can be confident it will work as expected when you need it most.

Create a Routine Maintenance Plan

Consistent maintenance prevents costly failures and unplanned downtime. Develop a cleaning schedule based on your facility’s environment and the manufacturer’s recommendations. High-traffic or high-contaminant areas may require monthly attention, while cleaner environments may allow for longer intervals.

Assign responsibility to trained personnel and maintain detailed records of each service event. Review maintenance logs during safety meetings to identify trends or recurring issues.

Partnering with an experienced supplier like TG Technical Services can help you select appropriate replacement parts and ensure proper care. A proactive approach protects both workers and infrastructure.

Keep Your Detection System Reliable

Routine cleaning protects the accuracy and lifespan of your equipment. A step-by-step guide to cleaning fixed gas detectors gives mechanical contractors and safety directors a practical framework for safe, effective maintenance. Clean sensors, documented inspections, and regular testing reduce the risk of missed gas leaks and unnecessary downtime.

TG Technical Services provides the gas-monitoring devices teams need to maintain safe operations nationwide. By following these steps and maintaining consistency, you can strengthen your safety program and protect everyone on site.